TUBESHEETS

Alexander Comley LTD holds OEM & end user approvals across Nuclear, Power, Process, Oil, Gas, Marine and Defence sectors. A market leading engineering company with a First Time Right approach to manufacturing complex, critical, pressure retaining parts.

Often referred to as a Shell and Tube Heat Exchanger, these are the most common used on oil refineries and chemical plants. Tubesheet production requires experience and manufacturing expertise.

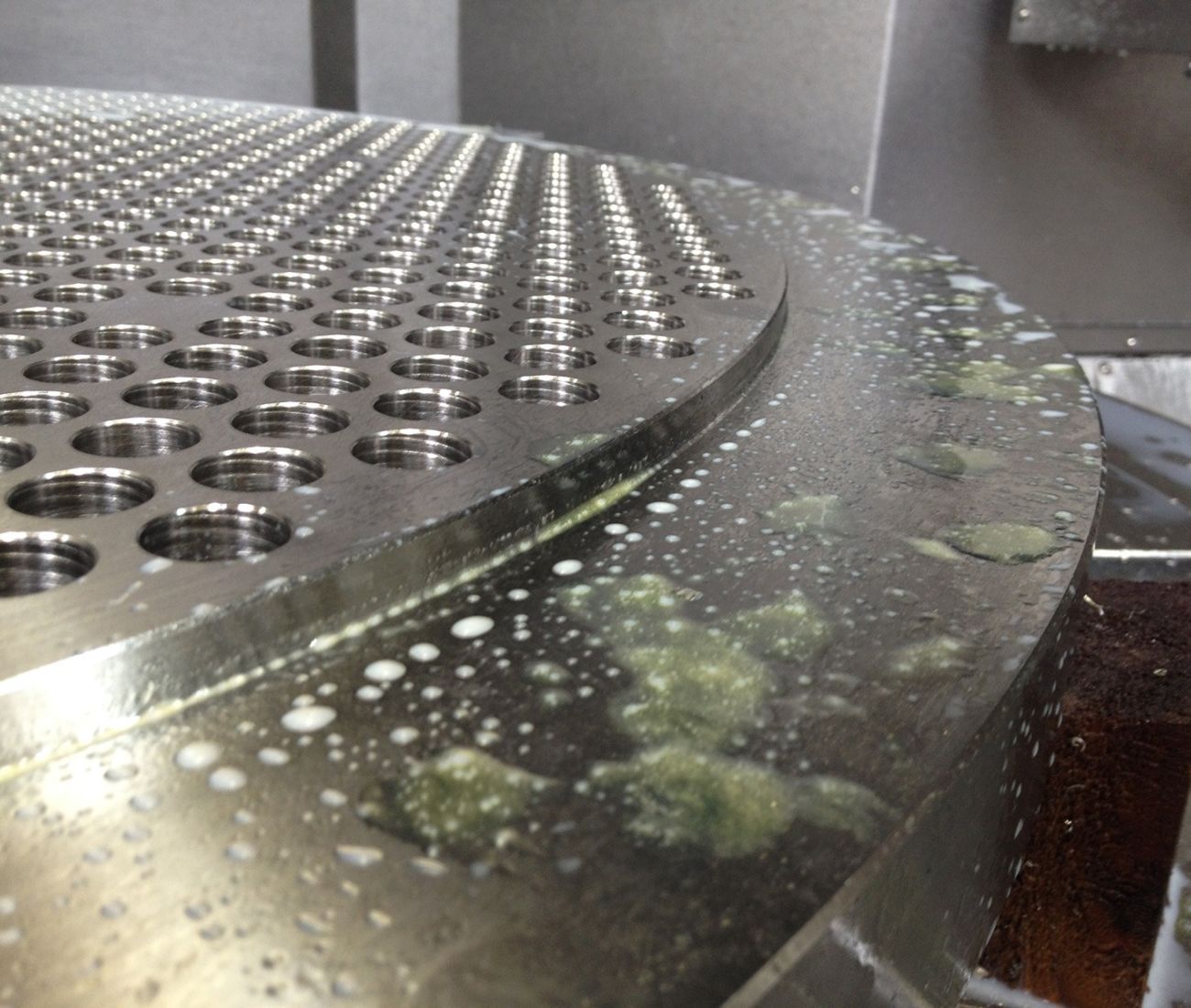

Fixed or Floating Tubesheets are the critical, internal component around which the entire tubular pressure vessel/heat exchanger is built. So called because holes are drilled specific ‘pitch’ configurations. Tubes carry hot/cold fluid through allowing the exchange of heat to occur.

-

Examples: Fixed Tubesheet | Floating Tubesheet.

-

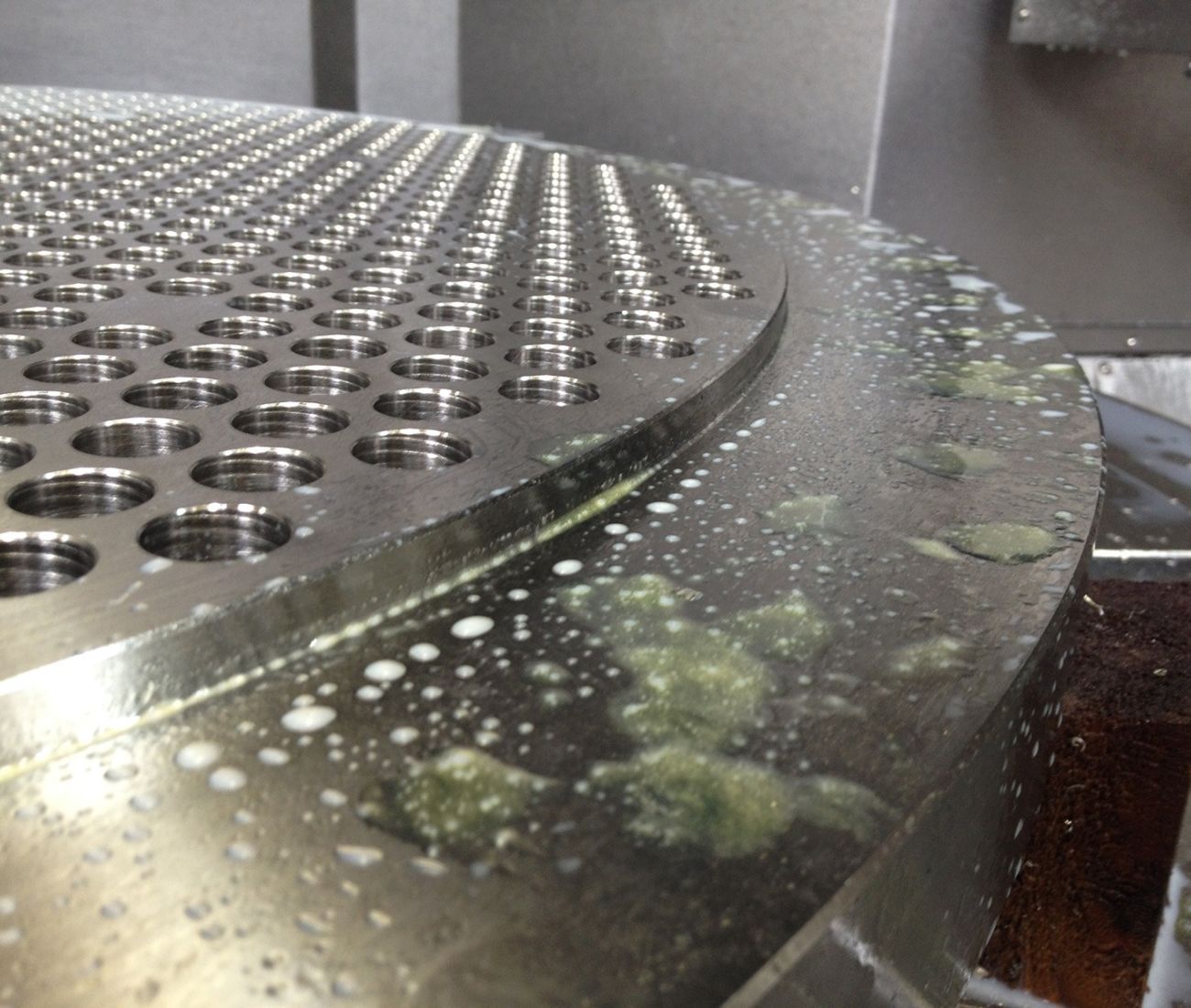

Examples: Tubesheet cladding + pre and post final machining.

-

In house CAD software to manufacture directly from DXF/STEP files.

-

Max capacity: 2,000 mm dia OD.

-

Materials: Stainless Steel, Carbon Steel, Titanium, Curonickel, Bronze, Brass Alloys, Naval Brass, Aluminum Bronze, Copper and many more.

-

Destructive testing: UKAS laboratories | tensile, charpy, hardness.

-

Non-destructive testing: UKAS laboratories | UT, DPI, MPI, PMI.

-

Certification: EN10204 3.1 | EN 10204 3.2.

We manufacture Flanges, Special Flanges, Filter Plates, Large Rings, Machined Components & Pipe Fittings.

We stock stainless steel flanges as B16.5, EN1092-1, B16.36 up to 24” NB, 2,500 lbs.

We source from supply chain, Plate, Fasteners, Gaskets & Pipe.

TUBESHEETS

Alexander Comley LTD holds OEM & end user approvals across Nuclear, Power, Process, Oil, Gas, Marine and Defence sectors. A market leading engineering company with a First Time Right approach to manufacturing complex, critical, pressure retaining parts.

Often referred to as a Shell and Tube Heat Exchanger, these are the most common used on oil refineries and chemical plants. Tubesheet production requires experience and manufacturing expertise.

Fixed or Floating Tubesheets are the critical, internal component around which the entire tubular pressure vessel/heat exchanger is built. So called because holes are drilled specific ‘pitch’ configurations. Tubes carry hot/cold fluid through allowing the exchange of heat to occur.

-

Examples: Fixed Tubesheet | Floating Tubesheet.

-

Examples: Tubesheet cladding + pre and post final machining.

-

In house CAD software to manufacture directly from DXF/STEP files.

-

Max capacity: 2,000 mm dia OD.

-

Materials: Stainless Steel, Carbon Steel, Titanium, Curonickel, Bronze, Brass Alloys, Naval Brass, Aluminum Bronze, Copper and many more.

-

Destructive testing: UKAS laboratories | tensile, charpy, hardness.

-

Non-destructive testing: UKAS laboratories | UT, DPI, MPI, PMI.

-

Certification: EN10204 3.1 | EN 10204 3.2.

We manufacture Flanges, Special Flanges, Filter Plates, Large Rings, Machined Components & Pipe Fittings.

We stock stainless steel flanges as B16.5, EN1092-1, B16.36 up to 24” NB, 2,500 lbs.

We source from supply chain, Plate, Fasteners, Gaskets & Pipe.

HAVE ANY QUESTIONS?

Click to send an email or call us. The team has decades of experience. 100 years of proud customer history can’t be wrong.

What we do

MANUFACTURER: special flanges (custom drawings), large flanges (international standards), up to 2,000 mm diameter.

STOCKIST: non-EU 316/L + 304/L stainless steel flanges up to 24” NB, 2,500 lbs (finished/semi-finished) to B16.5, B16.36, BS10 & EN1092-1.

PROJECT MANAGEMENT/PROCUREMENT SERVICES: from decades of managing projects, applying skill, knowledge and experience, as needed, we manage the entire supply chain across material(s) requisition, manufacturing, testing, certification and delivery to you.

Where we operate

GLOBALLY.

Alexander Comley LTD has established distribution agents in key countries worldwide.

Experienced in manufacturing supply to Oceania (Australia, New Zealand, Singapore, Japan), Africa (Angola, Ghana, Nigeria, Libya, S outh Africa), across the entirety of Europe, The Middle East (Kuwait, Bahrain, Qatar, United Arab Emirates, Oman, Saudi Arabia), North America (USA) and South America (Brasil).

Why choose us?

YOUR PROBLEM: Picture this: you’re on project site, deadline looming, in need of flanges, the plant down..

YOUR SOLUTION: you know Alexander Comley as experienced in manufacturing flanges up to 2,000 mm diameter, to complex specifications, with additional testing and certification..

YOUR CHOICE: Serving both domestic UK and International markets, we hold OEM/end user approvals across Nuclear, Power, Process, Oil, Gas, Marine and Defence sectors..

CONTACT US: Call or email us to fix your challenge. You place the PO. We deliver on time, in budget, wherever in the world you are. 100 years of proud history can’t be wrong.